from varmain.primitiv import *

from varmain.custom import *

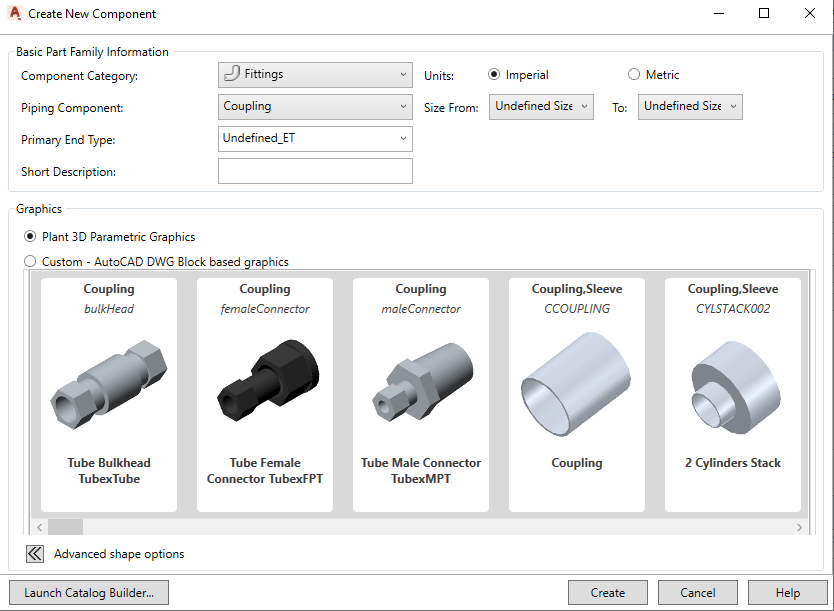

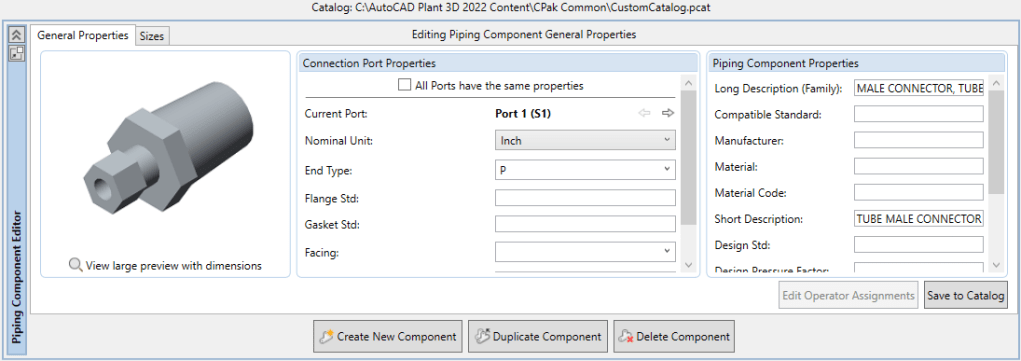

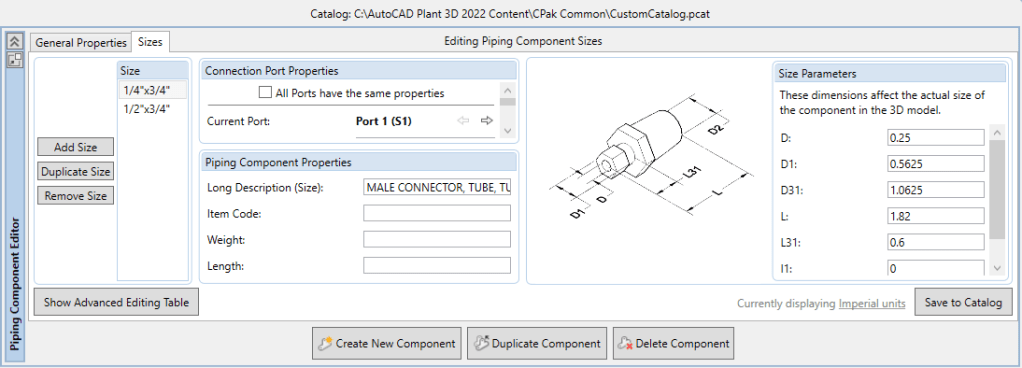

@activate(Group="Coupling", TooltipShort="Tube Male Connector TubexMPT", TooltipLong="Tube Male Connector TubexMPT", FirstPortEndtypes="P", LengthUnit="in", Ports="2")

@group("MainDimensions")

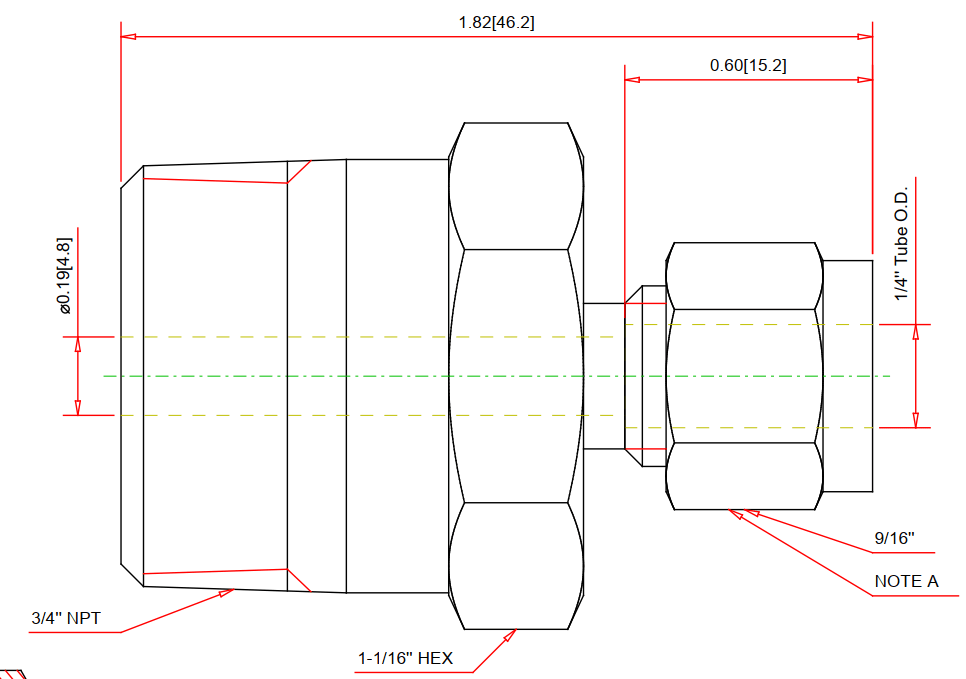

@param(D=LENGTH, TooltipShort="Tube OD", TooltipLong="Tube OD")

@param(D1=LENGTH, TooltipShort="Hex head OD", TooltipLong="Fitting hex head OD")

@param(D31=LENGTH, TooltipShort="Hex OD of Body", TooltipLong="Hex OD of Body")

@param(L=LENGTH, TooltipShort="Length of Fitting", TooltipLong="Overall Length of Fitting")

@param(L31=LENGTH, TooltipShort="Tube gland", TooltipLong="Tube gland length")

@param(I1=LENGTH, TooltipShort="Tube insert", TooltipLong="Tube insert distance")

@param(OF=LENGTH0)

#(arxload "PnP3dACPAdapter")

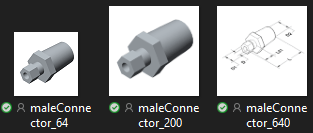

#(testacpscript "maleConnector")

def maleConnector(s, D=0.25, D1=0.5625, D31=1.0625, L=1.82, L31=0.6, I1=0, K=1, OF=0, **kw):

#length

L32 = L31*0.6 #adjusting the length of hex head

L33 = L - L31 #adjusting the length of hex head

L1 = 0.2 #adjusting the length of body

#hex head

headStartangle = 0

headBox1 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle) #cos(30deg) = 0.866

headBox2 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle+60) #cos(30deg) = 0.866

headBox3 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle+2*60) #cos(30deg) = 0.866

headBox4 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle+3*60) #cos(30deg) = 0.866

headBox5 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle+4*60) #cos(30deg) = 0.866

headBox6 = BOX(s, L=D1, W=D1, H=L32).translate((L32/2,0,1.866*D1/2)).rotateX(headStartangle+5*60) #cos(30deg) = 0.866

headBox1.uniteWith(headBox2)

headBox1.uniteWith(headBox3)

headBox1.uniteWith(headBox4)

headBox1.uniteWith(headBox5)

headBox1.uniteWith(headBox6)

headBox2.erase()

headBox3.erase()

headBox4.erase()

headBox5.erase()

headBox6.erase()

head1 = CYLINDER(s, R=D1/2, H=L32, O=0).rotateY(90)

head1.subtractFrom(headBox1)

headBox1.erase()

#body create

bodyMain = CYLINDER(s, R=0.8*D1/2, H=L, O=0).rotateY(90)

# hex head second

head2Startangle = 0

head2Box1 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle) #cos(30deg) = 0.866

head2Box2 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle+60) #cos(30deg) = 0.866

head2Box3 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle+2*60) #cos(30deg) = 0.866

head2Box4 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle+3*60) #cos(30deg) = 0.866

head2Box5 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle+4*60) #cos(30deg) = 0.866

head2Box6 = BOX(s, L=D31, W=D31, H=L33*0.2).translate((L33*0.2/2+L31,0,1.866*D31/2)).rotateX(head2Startangle+5*60) #cos(30deg) = 0.866

head2Box1.uniteWith(head2Box2)

head2Box1.uniteWith(head2Box3)

head2Box1.uniteWith(head2Box4)

head2Box1.uniteWith(head2Box5)

head2Box1.uniteWith(head2Box6)

head2Box2.erase()

head2Box3.erase()

head2Box4.erase()

head2Box5.erase()

head2Box6.erase()

head2 = CYLINDER(s, R=D31/2, H=L33*0.2, O=0).rotateY(90).translate((L31,0,0))

head2.subtractFrom(head2Box1)

head2Box1.erase()

head2F = CONE(s, R1=D31/2*0.85, R2=D31/2*0.7, H=L33, E=0).rotateY(90).translate((L31,0,0))

head2.uniteWith(head2F)

head2F.erase()

#joint 3 parts

bodyMain.uniteWith(head1)

bodyMain.uniteWith(head2)

head1.erase()

head2.erase()

#create a hole fitting

boreCy = CYLINDER(s, R=D/2, H=L, O=0).rotateY(90)

bodyMain.subtractFrom(boreCy)

boreCy.erase()

#tube insert distance

if I1 == 0:

I1 = L31

#set port points

s.setPoint((0.0 + I1, 0.0, 0.0), (-1.0, 0.0, 0.0), 0)

s.setPoint((L, 0.0, 0.0), (1.0, 0.0, 0.0), 0)

return

See PART 1: